Fire Fighting Safety Equipment Supplier

There are many types of butterfly valves, including quick cut-off and continuous adjustment, Pneumatic butterfly valves , electric butterfly valves are mainly used for liquid and gas low pressure large diameter pipelines. It is suitable for occasions where the pressure loss is not high, flow adjustment is required, and the opening and closing requirements are fast; usually the temperature is below 300 ℃ and the pressure is below 40 kg (butterfly valves generally use low pressure, like domestic ones. It is rare to achieve CL600). The medium is generally used for water and gas, and the medium is not demanding. Granular medium can also be used.

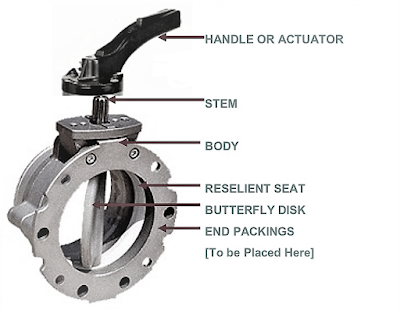

As a sealed butterfly valve, it brought rapid development after the emergence of synthetic rubber, so it is a new type of shut-off valve. Butterfly valves were mainly used for low-pressure valves, and the valve seat was made of synthetic rubber. By the 1990s, due to increased exchanges with foreign countries, hard seal but, hard seal butterfly valves developed rapidly. At present, there are many valve factories that can produce medium-pressure metal-sealed butterfly valves stably, which makes the application field of butterfly valves wider.

The media that the butterfly valve can transport and control are water, condensate, circulating water, sewage, sea water, air, gas, liquid natural gas, dry powder, mud, fruit pulp and mixtures with suspended solids.

Butterfly valves are suitable for flow regulation.

Since the pressure loss of the butterfly valve in the pipeline is relatively large, about three times that of the gate valve, when selecting the butterfly valve, the influence of the pressure loss of the pipeline system should be fully considered, and the strength of the butterfly plate to withstand the pressure of the pipeline medium should also be considered. In addition, it is necessary to consider the limitation of the working temperature of the elastic valve seat material at high temperature. The structural length and overall height of the butterfly valve are small, the opening and closing speed is fast, and it has good fluid control characteristics. The structural principle of the butterfly valve is most suitable for making large-diameter valves. When the butterfly valve is required to control the flow, the most important thing is to correctly select the size and type of the butterfly valve so that it can work properly and effectively.

1. Generally, in throttling, regulating control and mud medium, the structure length is short and the opening and closing speed is fast (1/4 revolution). Low pressure cut-off (small pressure difference), butterfly valve is recommended.

2. The butterfly valve can be used when two-position adjustment, narrow passage, low noise, cavitation and vaporization phenomenon, a small amount of leakage into the atmosphere, and abrasive media.

3. When the butterfly valve is used under special conditions, such as throttling adjustment, or strict sealing requirements, or severe wear, low temperature (cryogenic) and other operating conditions, it is necessary to use a specially designed metal seal with a triple eccentric or double eccentric adjustment device Special butterfly valve for ground.

4. The center line butterfly valve is suitable for fresh water, sewage, sea water, salt water, steam, natural gas, food, medicine, and oil that require complete sealing, zero gas test leakage, high life requirements, and working temperature of -10℃~150℃ And various acid and alkali and other pipelines.

5. The soft-sealed eccentric butterfly valve is suitable for two-way opening and closing and adjustment of ventilation and dust removal pipelines. It is widely used in gas pipelines and waterways in metallurgy, light industry, electric power, and petrochemical systems. Sendhamarai Engineering is the authorised dealer of Lehry Valves